ACG’s AF330 capsule filling machine for pharmaceutical and nutraceutical applications – prioritizing simplicity, safety, and efficiency in its design – is being displayed at CPHI and PMEC India 2023.

Its customer-centric concept design aims for low maintenance costs and minimal unplanned downtime, alongside high output and minimal footprint. Its latest HMI, or Human Machine Interface, is intended to facilitate intuitive, seamless operation. cream soft plastic tube filling sealing machine

The machine is expected to cut down on errors through its accelerated machine setup, which is said to shorten downtimes, improve yields, and increase productivity. Its IIoT-enabled system has been implemented to allow for machine health checks and facilitate both tracking and online monitoring.

Setting its sights on fulfilling the developing requirements of the pharmaceutical industry, ACG expects the AF330 to cut down on errors during setup, foreground safety, and achieve security in its operational environment.

Karan Singh, managing director at ACG, said “As we thrive to make it better for manufacturers in the pharmaceutical industry, this design ensures efficiency, minimal maintenance and speed - optimizing performance for manufacturers.

“A revolutionary step in capsule filling capability, it embodies the next generation of manufacturing excellence, setting new standards in efficiency and high productivity in smallest footprint. We are eager to showcase its groundbreaking features over the next few days.”

A similar development was unveiled by Syntegon in the summer. Its GKF Capsylon 6005 capsule filling machine is said to double the capacity of its previous model and fill 360,000 nutraceutical capsules every hour.

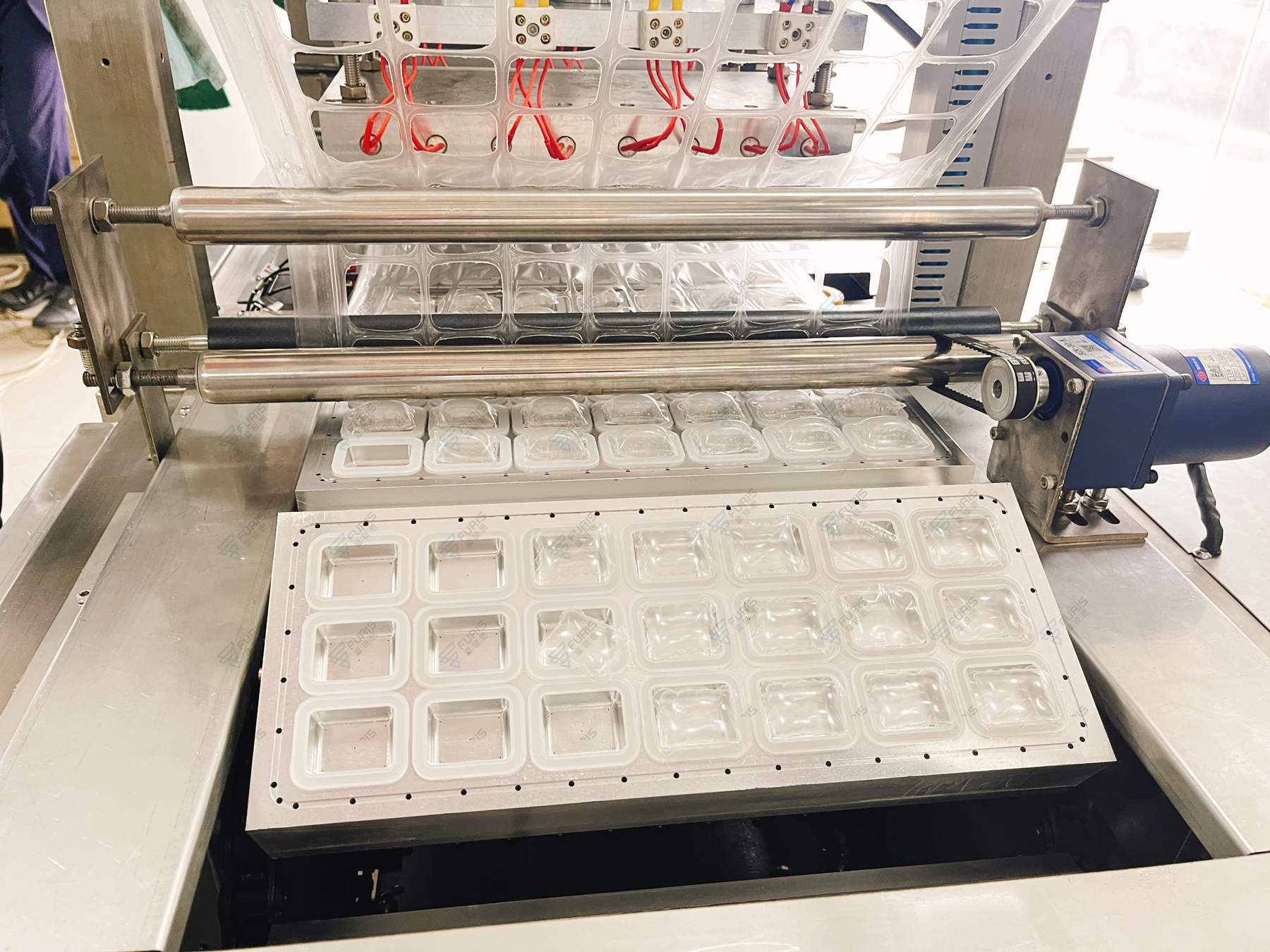

The company also debuted four new form, fill, seal machines at interpack 2023, gearing these developments towards a range of food applications.

At the same event, ROTZINGER Group showcased its FLK/VRM Filling & Capping machine. Combining the operations of a linear filler and rotative capper, it is set to fill liquids of various viscosities with a volumetric and mass-flow filling system.

If you liked this article, you might also enjoy:

The L’Oréal approach to packaging sustainability

The way we talk about plastic needs to change – here’s how to get it right

What steps is Apple taking to make its packaging more sustainable?

The Danone approach to packaging sustainability

bubbl bath bomb make machine Site powered by Webvision Cloud